- March 5, 2024

- Posted by: admin

- Categories:

Value and Waste

Staff 2

Imagine you are in charge of a production plant and you know that the cleaning process is fundamental to maintain efficiency and safety.

However, you are faced with the challenge of how to improve this process without increasing costs?

One customer was facing exactly this, our mission was clear: find improvement options without sacrificing quality or increasing costs.

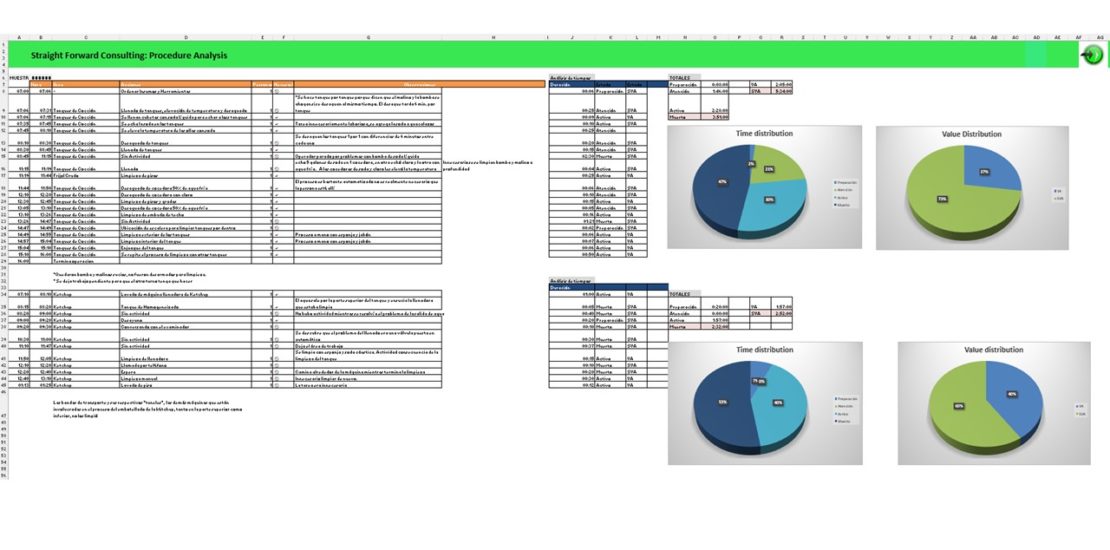

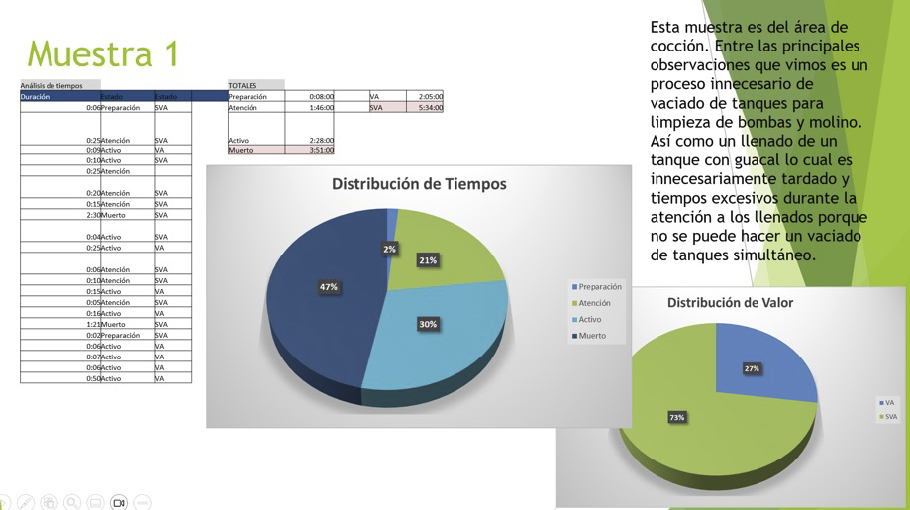

Our explorers immersed themselves in 14 hours of cleaning operations and during this investigation we not only performed a time analysis, but also studied the purpose of the actions, classifying the necessary tasks and those that did not add value to the operation.

We identified from repeated actions in a matter of minutes, to a lack of clarity about the next steps once the tasks were completed leading to numerous opportunities to improve and add value to the processes.

We recommended to our client to communicate clear processes, implement visual controls and assign new tasks relevant to the operation. This allowed them to improve the occupancy of their staff and take advantage of recovered time.

The result was an improvement of existing processes and the possibility of assigning new tasks for which it would have been necessary to hire more staff. This is how innovation and optimization can transform an organization without stretching its budget.