Overall Effectiveness

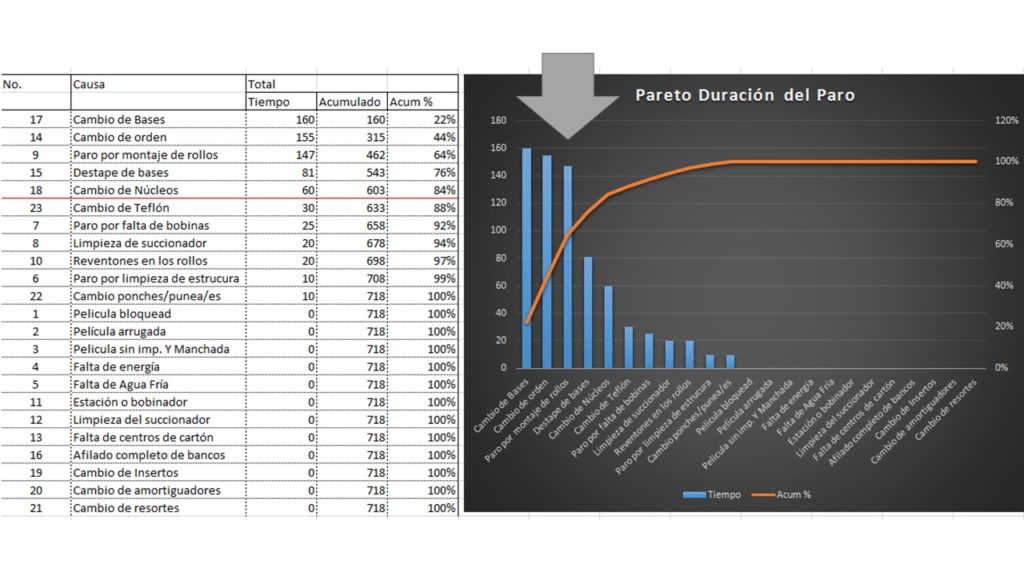

Pareto chart

Imagine this situation: you’re in charge of a company facing constant downtime and high maintenance costs. Sounds familiar?

A customer came to us with an urgent request: they needed to reduce their downtime and cut costs in maintenance.

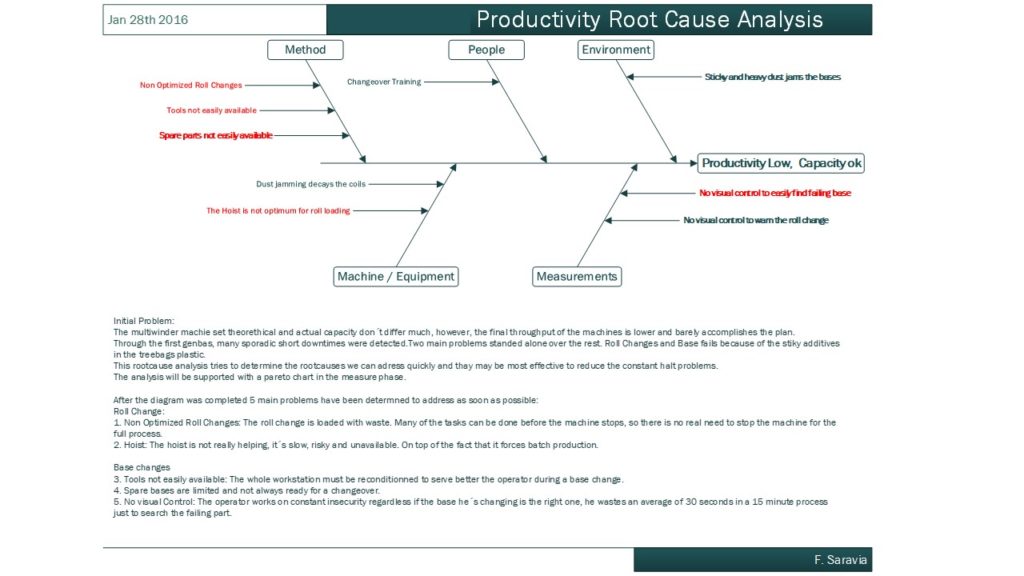

We conducted a thorough analysis of equipment productivity

We identified the most common causes of downtime and their frequency and variability over time. In addition to predicting the most common causes of downtime, we also developed a predictive maintenance and parts replacement program.

The application of our recommendations resulted in a 15% efficiency improvement.

Our customer now enjoys a more efficient operation with less downtime.